Product Description

AN ALL-IN-ONE POWERHOUSE

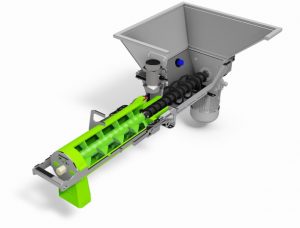

The MAI Multimix-3D is specially designed for 3D concrete printing application. Consisting of a dry material mixer with automatic water injection, a pumping unit, and an information display unit makes the whole printing process as convenient as possible.

INDEPENDENT MIXING AND PUMPING UNIT

The independent mixer and pump keeps both processes separated. This allows the mixer to operate at a consistent mixing speed, while keeping the pump’s flow rate variable without any quality fluctuation.

SELF-STABILIZING CLOSED-LOOP WATER CONTROL SYSTEM

The Multimix-3D is equipped a number of probes around its hoppers to detect if any material is in the machine. The probes prevent the machine from dry-running without any material, thus prolonging its lifespan.

MAI-PATENTED MIXING UNIT

Inside the Multimix-3d’s mixing tube is a customizable mixing unit that can be changed easily to suit any material specification.

INFORMATION DISPLAY AND INTELLIGENT CONTROL SYSTEM

A digital display is included, showing important information as well as MAI’s Intelligent Control System. It gives the user a complete control over the machine, parameters including :

- Water flow

- Water tolerance

- Delivery rate

- Vibrator adjustment

- Probe adjustment, and more

AGITATOR IN PUMP’S HOPPER

Agitator arm inside the pump’s hopper allows any concrete printing material to flow in easily, preventing clumps forming along the side of the hopper.

HIGH ENDURANCE BUILD MATERIAL AND QUALITY

The Multimix-3D is built to last. Stainless steel and hot-dip galvanized components provide corrosion protection, as well as MAI®CODUR synthetics making components that come in contact with the material high resistance and easy to clean.

| Operating Voltage | 400V/ 3/ PE/ 50Hz |

| Nominal Capacity | 10 kW |

| Fuse protection | 32A |

| Feed Capacity | 5 – 50 l/min (Default Configuration) |

| Dimension (cm) | 201 x 75 x 103 |

| Filling Height | 103 cm |

| Total Weight | 360 kg |