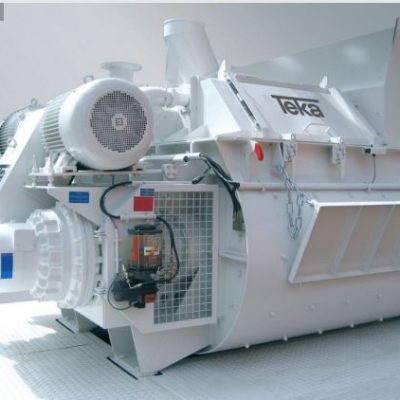

Product Description

In 2003 this continuous improvement process resulted in the launch of the revolutionary new ‘ swing back’ mixer arm. Unlike traditional vertically mounted arms, swing back arms are angled in 3 dimensions. This innovation improves mixing efficiency, eliminates dead zones and helps minimise cleaning.

- Intensive mixing minimises “balling”

- Shorter mixing and discharge times

- New rectangular flat blades for precise blending

- Few mixer arms, lower running build up

- Easier cleaning

Teka turbine pan-type Glass Batch mixers offer more mixing possibilities such as:

- Steam-injection through rotating lances, or through stationary nozzles.

- Mixer doubling as weigh-bin when mounted on load cells

- The spring-loaded mixing arms are mounted in the rotor head, and are adjustable to compensate for wear.

- This, plus their various angles of attack enhance the nix effect,reduce wear and protect the drive and shock.

- A protective cover encloses the mixers on top. A built in seal makes it near dust-proof.

- Large, hinged segments with variable positioning are possible, raised and lowered by a manual or motorized cable winch

The mixing pan floor and the outer walls are protected by exchangeable wear liners. The spring-loaded mixing arms are mounted in the rotor head and are adjustable to compensate for wear. This, plus the various angles-of-attack of the paddles enhance the mix-effect, reduce wear and protect the drive from shock

Central lubrication for the mixing arm bushings is available. Depending on the application, mixing paddles, wall scrapers, and mixing arm wear guards made of various abrasion- resistant materials are available. These include cast-iron W4, with complete tungsten-carbide surface, polyurethaneelastomere (PU), nickel-free special casting, etc.

The centrally located planetary gearbox is driven by a 3-phase TEFC motor which is fl angemounted directly to the gearbox, in the case of pan-type mixers THZ 375 to THZ 1125 turbine.

Mixer sizes THZ 1125 G to THZ 7500 are driven by a foot-mounted motor which is connected to the gear box by a universal joint cardan shaft. A hydraulic turbo coupling or frequency converter for soft starts under load are also available.

Flange to the gearbox and driven by it is a hydraulic gear pump which constantly cycles the oil. Gearbox and discharge gate(s) use the same oil for less maintenance. This oil also supplies the pressure to operate the discharge gate(s).

The discharge gate assembly, used to remove the batch from the mixer, is a complete heavy-duty component bolted to the mixer pan floor. The semi-circular gate is hydraulically operated by means of a rotating piston cylinder.

It is electrically controlled, and can be opened to any degree desired. The discharge gate is protected by a specially designed dust-free discharge protection. Locating the pivot-point of the gate slightly inside the pan circumference allows for a large opening and thereby, a fast discharge. In case of emergency, a manual hand pump for the discharge door is standard. As an option, the discharge gate can be opened independent of the mixer main drive, via a separate hydraulic power-unit

Mixers THZ 250 to THZ 1125 may be equipped with up to 4 gates, whereas 3 gates is the maximum for THZ 1125 G to THZ 7500. Sampling gates are also available.

Specifications:Glass Mixers

TPZ | 375 | 500 | 750 | 1125 | 1500 | 1875 | 2250 | 3000 | 3750 | 4500 | |

| Filling quantitymixer | litres | 375 | 500 | 750 | 1125 | 1500 | 1875 | 2250 | 3000 | 3750 | 4500 |

| Filling quantity mixer | kg | 500 | 680 | 1020 | 1530 | 2400 | 2550 | 3060 | 4080 | 5100 | 6120 |

| Mixing Cycles | Per hour | – | – | – | – | 15-20 | – | – | – | – | – |

| Drive power mixer | kW | 11 | 15 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 |

| Speed of rotor | rpM | 35 | 37 | 30.5 | 29 | 20 | 20 | 18.5 | 18.5 | 18.5 | 18.5 |

| Water flow meter pressure | bar | – | – | – | – | 4-6 | – | – | – | – | – |

| Weight of mixer | kg | 1500 | 1900 | 2500 | 3500 | 4200 | 4600 | 6500 | 7100 | 9500 | 10300 |

| Total diameter of mixer(Ø) | mm | 1700 | 1900 | 2210 | 2520 | 2520 | 2872 | 2992 | 3370 | 3840 | 3840 |

| Total height of mixer(h) | mm | 1305 | 1445 | 1423 | 1405 | 1530 | 1530 | 1630 | 1740 | 1910 | 1910 |