Product Description

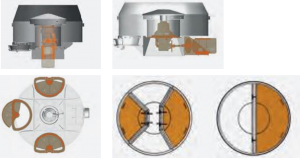

The spring-loaded mixing arms are mounted in the rotor head, and are adjustable to compensate for wear. This, plus their various angles-of attack enhance the mix-effect, reduce wear, and protect the drive from shock.

Depending on the appliction, mixing paddles, wall scrapers, and mixing arm wear guards made of various abrasion-resistant materials are available.The centrally located planetary gearbox is driven by a 3-phase TEFC motor, which is flange-mounted directly to the gearbox, in the case of THZ 375 to THZ 1125 mixers, and connected by a double universal joint driveshaft on THZ 1500 to THZ 5250 models. A hydraulic turbocoupling for soft starts under load is available also.Flanged to the gearbox, and driven by it, is a hydraulic gear pump which constantly cycles the oil, and supplies the pressure to operate the discharge gate(s).The THZ 250 employs permanently lubricated, flange gear motors for drive and discharge functions.

The discharge gate assembly, used to remove the batch from the mixer, is a complete component bolted to the mixer plan floor.

The semi-circular gate is hydraulically operated by means of a rotating piston cylinder. It is electrically controlled, and can be opened to any degree desired.

Locating the pivot-point of the gate slightly inside the pan circumference allows for a large opening and,thereby, a fast discharge.

Mixers THZ 375 to THZ 1125 may be equipped with up to 4 gates, whereas 3 gates is the maximum for THZ 1500 to THZ 5250.

A protective cover encloses the mixer on top. A built-in seal makes it near-dustproof. With no components located above the pan cover, there are no obstructions to impede the arrangement of cleaning segments, inspection doors, material inlets, etc. into the mixing pan.

Large, hinged segments are possible, raised and lowered by a manual- or motorized cable winch.

Depending on the plant design, charging the mixer by means of a skip hoist is available. Teka offers tilting skip hoists, as well as the nontilting, bottom discharge type. Standard inclinations of the hoist track is 60°. Inclinations from 45° to 90° may be specified.

Teka turbine mixers offer more mixing possibilities:

- Optional equipment includes intensive agitator(s) using various mixing tools. Retrofitting of agitators is possible.

- Moisture and consistency metering by means of floor-mounted, wall-mounted, or rotating electronic probes.

- Steam-injection through rotating lances, or through stationary nozzles.

- Mixer doubling as weigh-bin when mounted on load cells. High-pressure cleaning with rotating water spray nozzles.

| Models | THZ | 250 | 375 | 500 | 750 | 1125 | 1500 | 1500G | 1875 | 2250 | 3000 | 3750 | 4500 | 5250 |

| Filling quantity mixer | litres | 250 | 375 | 500 | 750 | 1125 | 1500 | 1500 | 1875 | 2250 | 3000 | 3750 | 4500 | 5250 |

| Filling quantity loose aggregates | kg | 400 | 600 | 800 | 1200 | 1800 | 2400 | 2400 | 3000 | 3600 | 4800 | 6000 | 7200 | 8400 |

| Compacted con- crete output p.cy | m³ | 0,15 | 0,25 | 0,33 | 0,5 | 0,75 | 1,0 | 1,0 | 1,25 | 1,5 | 2,0 | 2,5 | 3,0 | 3,5 |

| Drive power mixer | kw | 7,5 | 11 | 15 | 22 | 30 | 37 | 37 | 45 | 55 | 75 | 90 | 110 | 132 |

| Speed of rotor | rpm | 37 | 37 | 30,5 | 29 | 29 | 20 | 20 | 20 | 20 | 18,5 | 18,5 | 18,5 | 18,5 |

| Weight of mixer | kg | 900 | 1500 | 1900 | 2500 | 3500 | 4200 | 4600 | 4600 | 6500 | 8600 | 9500 | 10300 | 11600 |

| Filling capacity of skip hoist bucket 60º | kg | 375 | 550 | 750 | 1100 | 1650 | 2200 | 2200 | 2700 | 3250 | 4300 | 5400 | 6450 | – |

| Drive power skip hoist | ||||||||||||||

| multi – layerdrum | kW | 2,2 | 3 | 4 | 5,5 | 7,5 | – | – | – | – | – | – | – | – |

| single – layerdrum | kW | – | – | 5,5 | 7,5 | 11 | 15 | 15 | 16,5 | 20,5 | 20,5 | 30 | 37 | – |

| Speed of skin hoist bucket | m/Sec | 0,33 | 0,33 | 0,33 | 0,4 | 0,4 | 0,4 | 0,4 | 0,36 | 0,4 | 0,36 | 0,36 | 0,34 | – |

| Weight of bucket | kg | 360 | 550 | 800 | 1000 | 1700 | 2000 | 2100 | 2200 | 3000 | 4000 | 5100 | 5100 | – |

Dimensions | T H Z | A | B | C | D | E | F | G | I | K | L | M |

in mm rounded | 250 | 850 | 300 | 600 | 1354 | 780 | – | 500 | 930 | 1045 | 2130 | 1200 |

375 | 935 | 370 | 700 | 1700 | 765 | – | 550 | 1000 | 1100 | 2270 | 1300 | |

500 | 1035 | 410 | 860 | 1900 | 860 | – | 650 | 1085 | 1330 | 2440 | 1400 | |

750 | 1150 | 473 | 1000 | 2210 | 1000 | – | 750 | 1185 | 1510 | 2740 | 1600 | |

1125 | 975 | 430 | 1100 | 2520 | 1175 | – | 900 | 1375 | 1790 | 2760 | 1800 | |

1500 | 1100 | 430 | 1100 | 2520 | 1175 | 1423 | 1050 | 1520 | 2020 | 3020 | 2000 | |

1500G | 1150 | 380 | 1300 | 2872 | 1350 | 1423 | 1150 | 1520 | 2020 | 3055 | 2000 | |

1875 | 1150 | 380 | 1300 | 2872 | 1350 | 1678 | 1150 | 1570 | 2020 | 3190 | 2100 | |

2250 | 1300 | 330 | 1300 | 2992 | 1410 | 1678 | 1150 | 1740 | 2210 | 3430 | 2200 | |

3000 | 1300 | 440 | 1500 | 3370 | 1575 | 1862 | 1350 | 2000 | 2460 | 3760 | 2600 | |

3750 | 1600 | 310 | 1600 | 3840 | 1800 | 2317 | 1350 | – | – | – | – | |

4500 | 1600 | 310 | 1600 | 3840 | 1800 | 2456 | 1350 | – | – | – | – | |

5250 | 1600 | 320 | 1800 | 4350 | 2060 | 2400 | 1350 | – | – | – | – |

**Dimension subject to changes without prior notice.